- Custom Performance with ASIC Effort

- 3X Faster than ASIC

- 40% Smaller than ASIC

- 10X Less Effort than Full Custom

The Tool for High Performance

Designs

DPC is the tool used by designers needing high performance chips. They want the performance of full custom design, but with a much shorter design cycle. Datapaths designed with DPC are 3X (three times) faster and 40% smaller than synthesis and place and route. At the same time, it takes 10X (ten times) less effort than full custom design.

In deep sub-micron design, wire length is the dominant factor affecting critical path timing. Cell placement becomes a critical step in chip performance as well as power consumption. With traditional tools, designers are at the mercy of automatic placement tools. The DataPath Compiler (DPC) lets the designer control placement with immediate timing feedback. Multiple what-if experiments can be performed. Using a graphical display that back annotates timing to the schematic, you can easily identify timing problems and rapidly iterate through potential solutions, yielding faster results. DPC is so fast it can place, and then time, a 50K gate datapath in 2-3 minutes.

Useful Identification of Critical Paths

DPC predicts wire lengths early in the design cycle. The resulting timing iterations are both fast and accurate, allowing the designer to quickly iterate to their performance goal. The critical paths are displayed directly on the schematic at all levels of the design hierarchy. In addition, the actual delays of the paths are annotated onto the wires in both the schematic and placement view. |

|

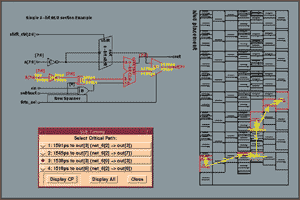

Figure 1-a. Figure 1-a.

The example above shows the placement generated for our sample 8-bit ALU. A critical path is highlighted in red and yellow on both the schematic and placement views. Timing for other nets is indicated in the menu and new nets can be selected and highlighted.

DPC for Critical Path Optimization

In datapath designs, some simple directives by the designer can produce speed-optimized layouts. These directives are easily given and modified in DPC. The placement of components on the schematic directs relative placement in the placement file.

Cells can also be hard placed at specific row or column locations and empty space can be indicated. DPC automatically generates the row and column placement and predicted wire lengths. Wire predictions can be used to drive the built-in DPC timing analyzer as well as standard timing analyzers including Pearl, PrimeTime and PathMill.

|

|